Fine cutting

Exact cutting edges with minimal heat input

Cutting with ultrashort pulsed laser radiation

When fine cutting with ultrashort pulse lasers, the material is vaporized in the cutting gap with minimal heat input into the surrounding material. This prevents the formation of melt and produces high-quality cutting edges. Right-angled cutting edges can be achieved by adjusting the laser beam during the machining process.

The advantages of fine cutting with the ultrashort pulse laser are as follows:

Perfect cutting quality

thanks to minimal heat input and avoidance of oxidation when using a process gas.

Right-angled cutting edges possible when using trepanning optics.

Cutting of thin and heat-sensitive materials such as thin foils (<20 µm) or composite materials is possible.

Right-angled cutting edges possible when using trepanning optics.

Cutting of thin and heat-sensitive materials such as thin foils (<20 µm) or composite materials is possible.

Fine cutting ─ machinable materials

The ultrashort pulsed laser can cut a wide variety of materials, such as ferrous and non-ferrous metals

(steel, aluminum, brass, copper, precious metals, ...), ceramics, glass

or composite materials

such as carbon fiber reinforced plastics (CFRP). The material thickness that can be machined is up to 2 mm, depending on the material.

The technology of fine cutting

The ultrashort pulse laser is the appropriate tool for cutting heat-sensitive

or difficult-to-machine

materials. Heat-sensitive materials can be, for example, very thin metals with a thickness of only a few 10 µm, composite materials with a plastic matrix or plastic foils. Materials that are difficult to machine are for example ceramics or glass. If pulse durations in the range of a few picoseconds and shorter are used, the material in the focus evaporates quasi instantly with minimal heat input into the remaining material. With each laser pulse, the material is ablated piece by piece until it is cut through. Thanks to non-linear absorption effects, even normally transparent materials can be processed.

A special feature of cutting with the ultrashort pulse laser is the shape of the cutting edge. If work is carried out without special optics for beam shaping, for example with a scanner system, the beam profile does not result in a right-angled cut edge. On the beam entry side, a rounded edge is formed which merges into a cut edge with a certain taper angle. The beam exit side is sharp-edged. The advantages of this type of cutting with the ultrashort pulse laser are the high processing speed and the narrow cutting gap.

If the cutting edge must be as vertical as possible, special processing optics are required. This moves the laser beam on a circular path while simultaneously adjusting the laser beam. This principle is illustrated in the following picture.

If the cutting edge must be as vertical as possible, special processing optics are required. This moves the laser beam on a circular path while simultaneously adjusting the laser beam. This principle is illustrated in the following picture.

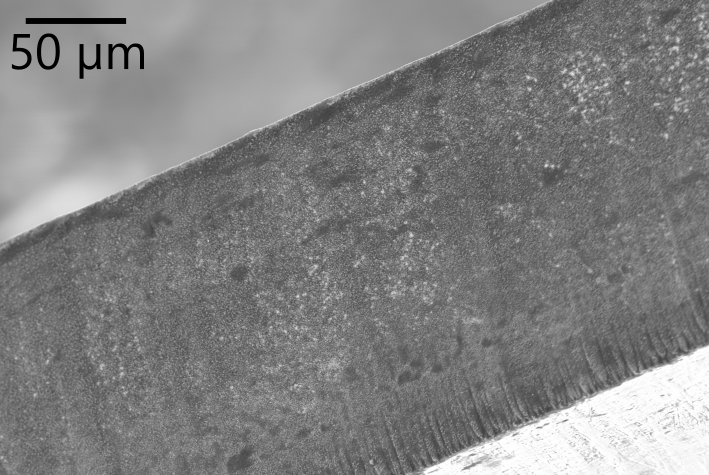

Since the absorption properties of the material depend on the angle of incidence, the taper angle of the cutting edge can be influenced. Thus, rectangular

and very sharp cutting edges

are possible, as shown in the following SEM image. The kerf is usually a little wider compared to a cut without the use of special processing optics, but the quality of the processing is also higher. As can be seen in the picture, the cut edges have only a slight roughness.