Surface machining

Variety in surface design

Processing surfaces with the ultrashort pulse laser

Due to the low heat input into the workpiece and the achievable accuracies, ultrashort pulse lasers are used to create highly precise and functional surface structuring by laser ablation. Different subtractive processes can be realised, such as structuring/texturing, micro engraving or selective thin-film ablation. These processes are used in a wide range of industries. LightPulse

LASER PRECISION is your industrial partner for the development and implementation of high-quality surface treatment processes.

Surface machining

Machining with the ultrashort pulse laser is an ablative process. By removing material, a wide variety of machining processes can be realised. In the following, some processes are briefly presented, more detailed information can be found on the respective pages:

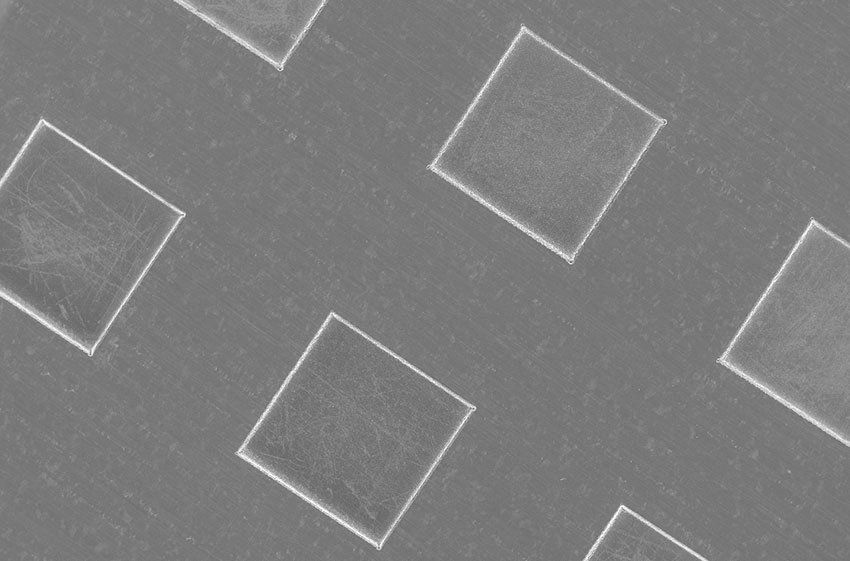

Structuring/Texturing.

Thanks to their good beam quality, ultrashort pulse lasers can be focused well on the smallest diameters. This means that contours down to 20 µm can be cleanly machined with tolerances in the micrometre range.Micro engraving.

With the correct process control, the heat input into the material remains minimal and quality-reducing effects such as melting, burr formation, bulges or roughening of the surface are avoided. This enables high-quality material processing with tolerances of a few µm.

Selective thin-film ablation.

As a non-contact tool, the laser processes material virtually without force. This means that even very thin materials can be processed reliably and precisely. For example, layers with thicknesses of a few 100 nm to a few µm can be cleanly removed from a carrier substrate.

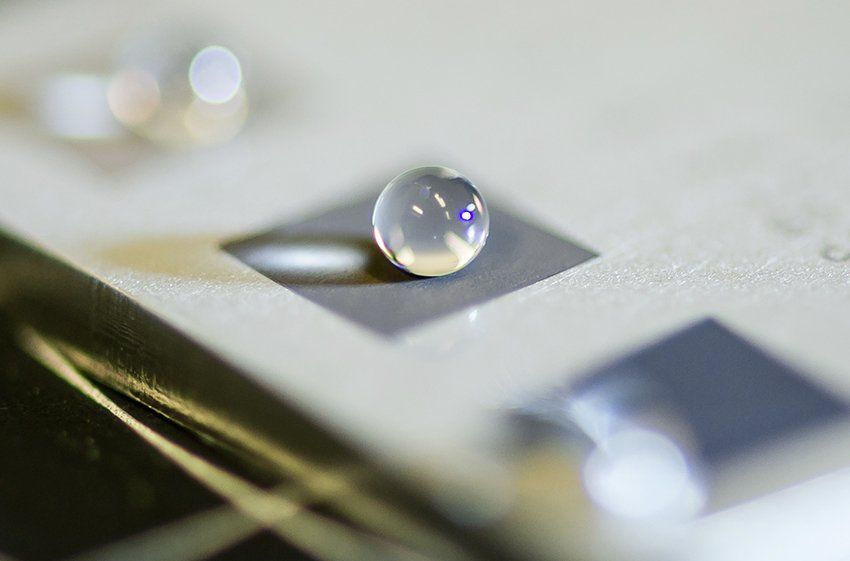

Surface functionalisation.

The functional properties of surfaces can be specifically changed by structuring with ultrashort pulse lasers. For example, laser-generated structures can be used to make a steel surface water-repellent (hydrophobic).

For more information on the processes

that are possible with the ultrashort pulse laser, click on the corresponding images: