General information

More information on micromachining with ultrashort pulse lasers

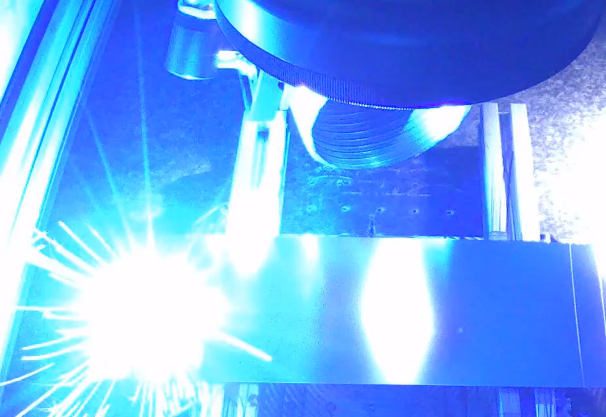

Micromachining with the ultrashort pulse laser

Micromachining with the ultrashort pulse laser covers a wide range of topics in addition to the actual laser processes. Here you will find information on the machinability of different materials as well as on the safety-critical topic of generating X-rays when machining materials with the ultrashort pulse laser.

More topics on ultrashort pulse laser processing:

Materials.

The laser is a versatile tool that allows the processing of a wide variety of materials. Metals, ceramics and plastics are typical examples of applications. Thanks to non-linear absorption effects, transparent materials such as glass can also be processed.

X-ray emissions: Due to the ultrashort pulses, very high intensities are typically achieved on the workpiece. This leads to ionisation of the ablated material and finally to the emission of X-rays. In addition to the laser radiation itself, this is one of the potential dangers when processing materials with the ultrashort pulse laser.

X-ray emissions: Due to the ultrashort pulses, very high intensities are typically achieved on the workpiece. This leads to ionisation of the ablated material and finally to the emission of X-rays. In addition to the laser radiation itself, this is one of the potential dangers when processing materials with the ultrashort pulse laser.