Rotary machining

Laser turning and cylinder machining with µm precision

Rotationally symmetrical components machined precisely

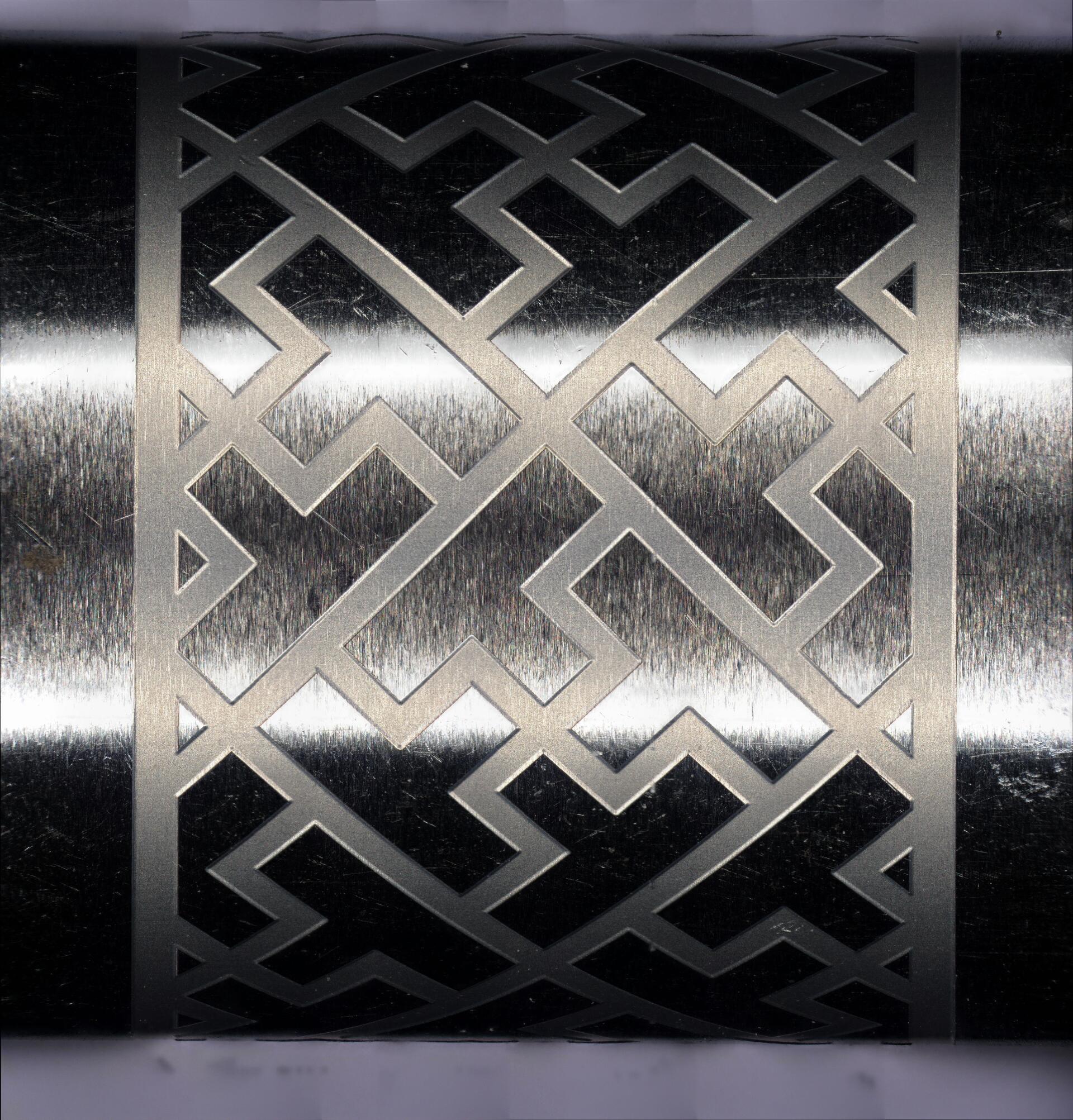

With the ultrashort pulse laser, rotationally symmetrical components can also be precisely machined. The centrepiece is a rotary axis with high-precision concentricity. Laser turning achieves the smallest diameters down to 50 µm. When machining cylinders, a structuring process applies predefined structures with an accuracy of a few µm while the component is rotating.

The advantages of rotary processing with the ultrashort pulse laser are:

Non-contact machining

- the workpiece experiences no forces and thus no deformation. This means that even the smallest diameters can be realised.

Minimal heat input thanks to pulse-on-demand, whereby the number of laser pulses is adapted to the current diameter of the workpiece.

High machining quality with roughness down to <1 µm.

Automated process for highest dimensional accuracy.

Minimal heat input thanks to pulse-on-demand, whereby the number of laser pulses is adapted to the current diameter of the workpiece.

High machining quality with roughness down to <1 µm.

Automated process for highest dimensional accuracy.

Machinable materials

The ultrashort pulse laser can be used to turn a wide variety of materials such as ferrous and non-ferrous metals

(steel, aluminium, brass, copper, precious metals, ...), ceramics, glass

or composite materials

such as carbon fibre reinforced plastics (CFRP). The picture on the left shows a laser-turned sapphire part. The machined surface has less roughness than the original surface.

Currently, blanks with a maximum diameter of 10 mm can be processed.

Currently, blanks with a maximum diameter of 10 mm can be processed.

The technology of rotary machining

In turning machining, the workpiece is clamped on a rotary axis with high-precision concentricity. There are essentially two types of turning machining: laser turning

and cylinder machining.

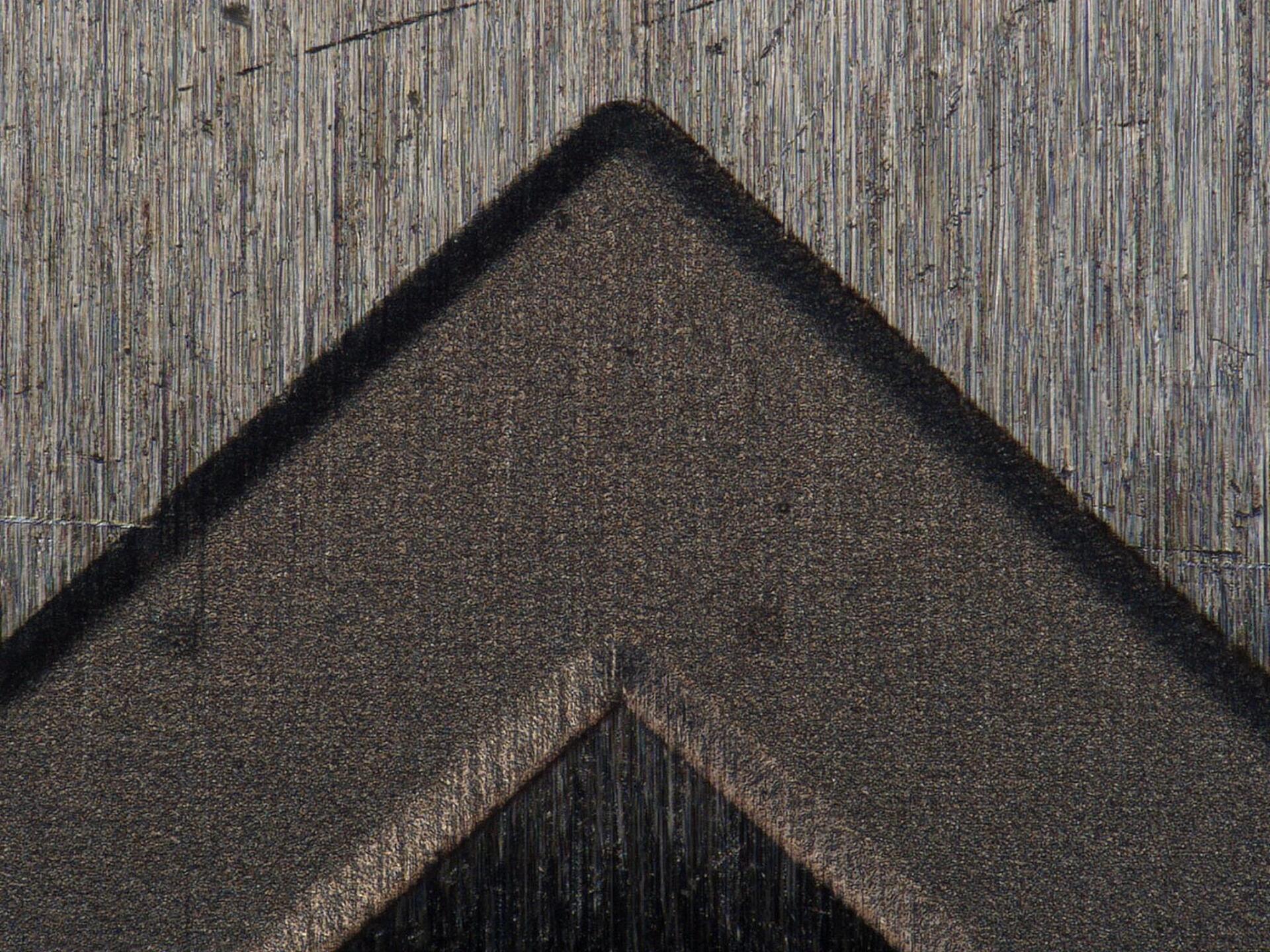

With both machining methods, the workpiece is rotated at a constant rotational speed. The difference is found in the positioning of the laser beam relative to the workpiece. In cylinder machining, the laser beam is focused on the top of the cylinder and the desired geometry is created by laser ablation. In laser turning, the laser beam is positioned laterally (tangentially) to the workpiece. By reducing or increasing the distance of the laser beam to the axis of rotation, different diameters can be realised. This process principle is similar to classic turning processes, hence the term laser turning as the name for this machining process.

Design freedom and pecision

The use of the ultrashort pulse laser for rotary machining opens up a multitude of possibilities for the production of rotationally symmetrical components. This results in a multitude of advantages:

The ultrashort pulse laser is a force-free tool. This means that no deformations occur during machining and parts with a large clamping length can also be machined. Due to the lack of forces during machining, diameters of less than 50 µm can be realised.

The good automation capability is another feature of the ultrashort pulse lasers. This means that the structures and diameters to be produced can be specified via a CAD file and are taken over directly by the machine. This enables a higher precision than, for example, with manual grinding processes. Furthermore, this offers a great deal of freedom in the design of the turned part or the structure.

The ultrashort pulse laser in itself is a high-precision tool. This can also be transferred to rotationally symmetrical components. Thus, structures with an accuracy of <5 µm can be created on cylinders.

Furthermore, the heat input is minimal when processing with ultrashort pulse lasers. This makes it possible to produce rotationally symmetrical components without impairing the microstructure or thermal stresses caused by heat input. If the diameter decreases during laser turning, excessive heat input can be achieved by adjusting the repetition rate of the laser (pulse-on-demand). This ensures a consistently high machining quality.

The ultrashort pulse laser is a force-free tool. This means that no deformations occur during machining and parts with a large clamping length can also be machined. Due to the lack of forces during machining, diameters of less than 50 µm can be realised.

The good automation capability is another feature of the ultrashort pulse lasers. This means that the structures and diameters to be produced can be specified via a CAD file and are taken over directly by the machine. This enables a higher precision than, for example, with manual grinding processes. Furthermore, this offers a great deal of freedom in the design of the turned part or the structure.

The ultrashort pulse laser in itself is a high-precision tool. This can also be transferred to rotationally symmetrical components. Thus, structures with an accuracy of <5 µm can be created on cylinders.

Furthermore, the heat input is minimal when processing with ultrashort pulse lasers. This makes it possible to produce rotationally symmetrical components without impairing the microstructure or thermal stresses caused by heat input. If the diameter decreases during laser turning, excessive heat input can be achieved by adjusting the repetition rate of the laser (pulse-on-demand). This ensures a consistently high machining quality.